8 READ-TIME

Fungicide modes of action

July 2, 2021

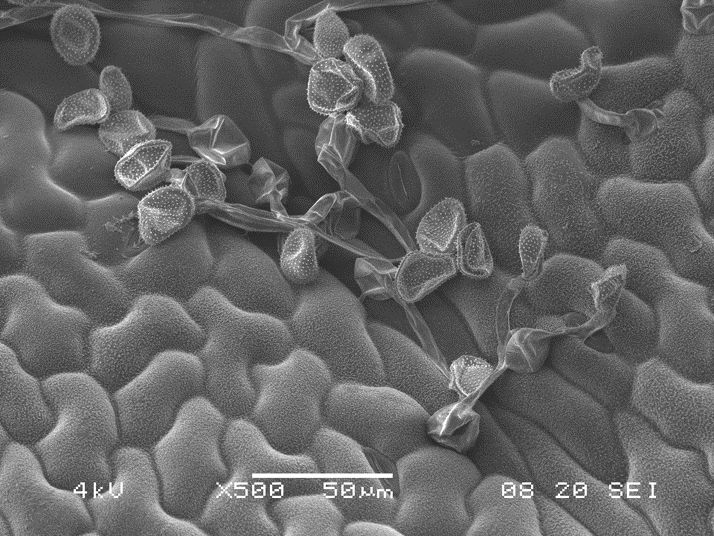

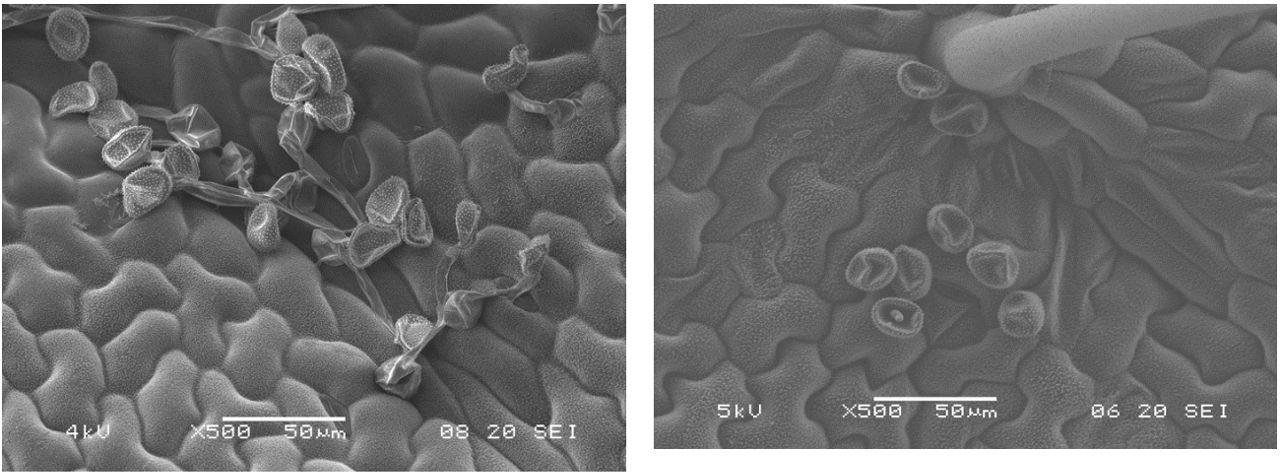

Fungicides are applied to help control or suppress plant diseases in broad acre and specialty horticulture crops. While field crops can be infected by fungal, bacterial, or viral diseases, fungicides are only active on fungal diseases. Fungal diseases occur when fungal spores germinate and penetrate a plant. The fungus grows in, on, and through the plant, and may reproduce, releasing spores that can lead to secondary infections (Figure 1).

Figure 1. Fungal spores germinated on leaf surface.

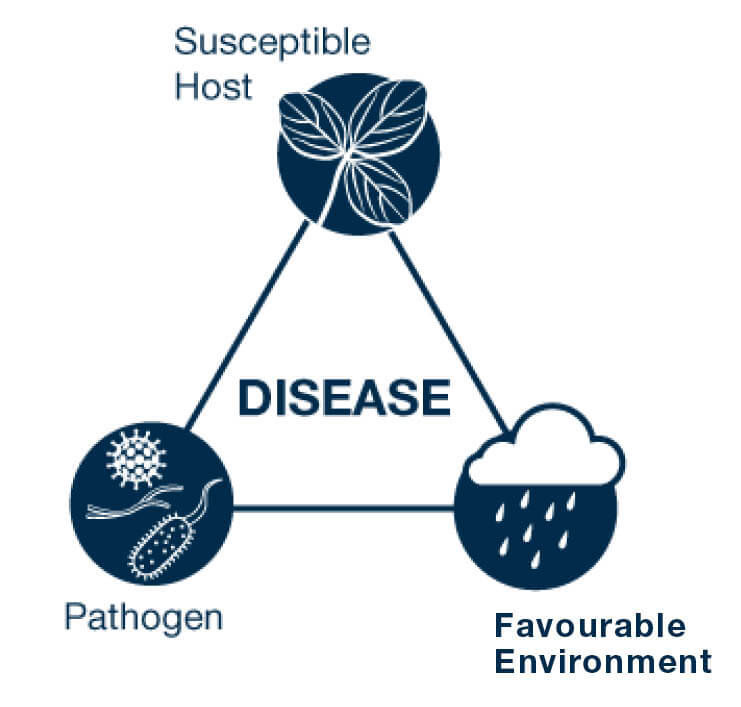

For fungi to infect the crop, the fungi (pathogen), the host (crop), and a favourable environment must all be present at the same time (Figure 2).

Figure 2. The disease triangle shows how pathogen, host, and environment are all required for infection to occur.

Crop rotation, genetic resistance, crop residue management, plant density, weed management, and irrigation management are parts of an integrated pest management program that can help reduce fungal infection by eliminating the host crop, manipulating the environment, or reducing pathogen populations for the future. Fungicides are another tool that can be used to help protect the crop from fungal disease. How fungicides work to prevent or reduce infection varies. The main classifications are described below.

Contact or Systemic

Contact fungicides can also be called protectant fungicides. They work on the leaf surface to prevent fungal spores from germinating or penetrating the plant. These fungicides require the most care in application as complete coverage is essential for effectiveness.

Systemic (or penetrant) fungicides work inside the plant and can be locally systemic or translocated throughout the plant. Systemic fungicides can be preventative and curative.

Preventative or Curative

Preventative fungicides prevent fungal infection to the plant. Curative fungicides can enter the plant and stop fungal infection after it has occurred. Curative fungicides can help prevent spore infection from spreading and forming lesions, and producing fruiting bodies and spores, to ultimately prevent re-infection. Fungicides cannot repair damaged tissue caused by fungal infection; therefore, fungicides should be used before serious infection has occurred.

Common Modes of Action

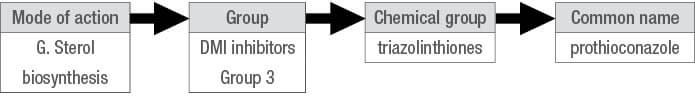

The levels of classification for fungicides are:

- Mode of Action

- Group

- Chemical Group

- Common Name

The Mode of Action describes what process is impacted in the fungi and is denoted with a letter code. The Group describes the target site, the specific site of activity of the fungicide. Fungicides can have the same mode of action but different target sites. For example, both demethylation inhibitors and amines inhibit sterol biosynthesis, but they work on different target sites to do this. All chemicals within a Group are generally considered cross-resistant to each other. The Chemical Group classifies like chemicals and the Common Name is synonymous to the active ingredient.1

Figure 3. Levels of classification for prothioconazole.

There are 13 Mode of Action classes. The most common fungicide modes of action are Respiration Inhibitors (C) and Sterol Biosynthesis Inhibitors (G). Other modes of action widely used are chemicals with Multi-Site Activity (M) and Biologicals with Multiple Modes of Action (BM). Of the Respiration Inhibitors, Group 7 and Group 11 are the most widely used. Group 29 fungicides are also Respiration Inhibitors with a different target site. Of the Sterol Biosynthesis Inhibitors, Group 3 fungicides are most widely used.

Respiration Inhibitors (C)

Group 7- Succinate dehydrogenase inhibitors (SDHIs)

SDHIs have a narrower spectrum of control than other fungicides and are highly active on the diseases that they target. SDHIs have longer residual activity than other groups. Systemic activity can be locally systemic to systemic. SDHIs are generally preventative and the main fungicide activity prevents fungal spore germination on the leaf surface (Figure 4). SDHIs can also have some curative properties as well as plant health and greening effects on crops. The mode of action is the inhibition of cellular respiration and energy production in the fungi. The target enzyme is succinate dehydrogenase.

Figure 4. Grape powdery mildew (Erysiphe necator). Left: Untreated. Right: Treated with fluopyram.

There are ten chemical groups in the SDHI group. These have either a benzamide, amide, or carboxamide group. Fungicides with a carboxamide group tend to have an enhanced greening effect compared to other SDHI fungicides. Carboxamide fungicides include benzovindiflupyr, bixafen, fluxapyroxad, penflufen, penthiopyrad, boscalid, and pydiflumetofen.

SDHIs have a moderate to high risk rating for resistance. These fungicides should be used early in the disease cycle when they are most effective. Relying on the curative properties of SDHIs can increase risk for resistance in fungal populations. Use the label rate and interval as repetitive, reduced rates can increase selection pressure and risk of resistance. Applying the fungicides in mixtures where each mix partner provides control of disease at the rate used in the mixture can help reduce selection pressure on the SDHI fungicide. In cereal and soybean crops, no more than two applications of SDHI fungicides should be used per crop per year. Where multiple applications are required, mixtures and rotation with other fungicide groups can help reduce the selection pressure on the SDHI fungicide. See FRAC recommendations for specific crops for more information.1

Group 11- Quinone outside inhibitors (QoIs)

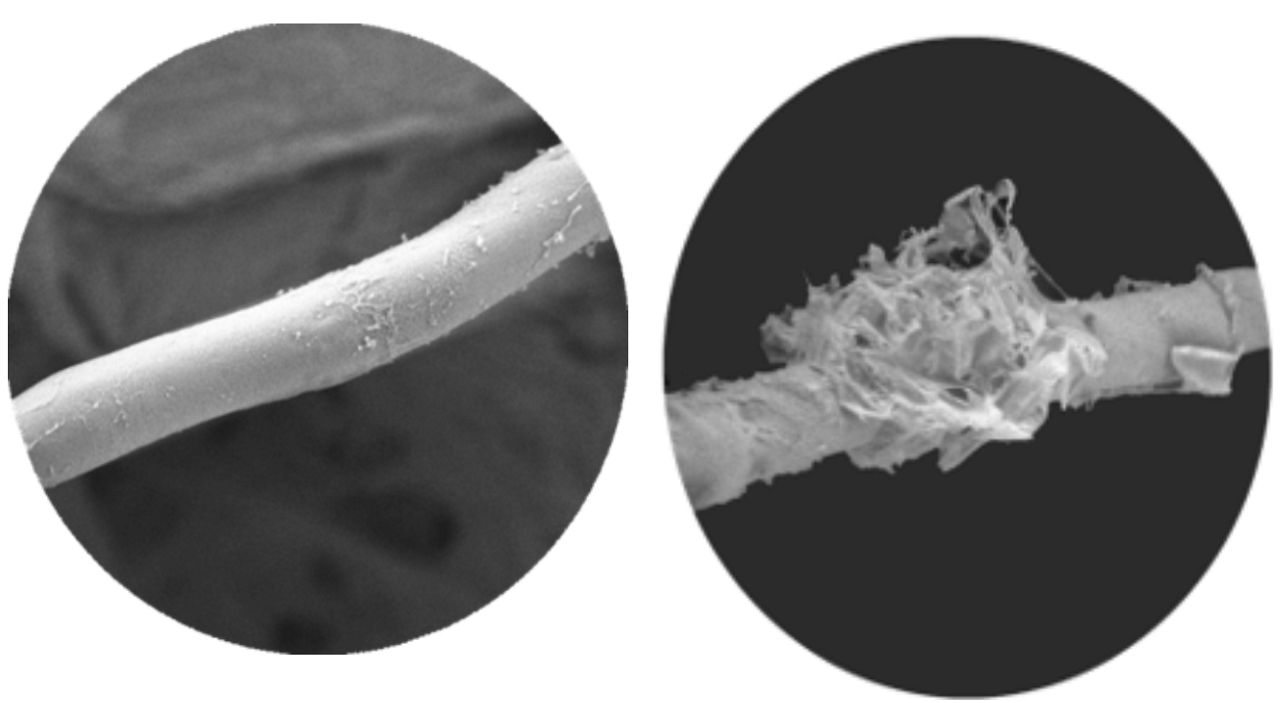

QoIs are broad-spectrum, preventative fungicides with limited to no curative activity. They differ in systemic properties from locally systemic through the leaf to systemic upwards movement through the xylem. Strobilurins are the most commonly used QoI fungicides. Some strobulurins, including trifloxystrobin, have a vapour phase. In the vapour phase, fungicide can move from leaf to leaf. Once it moves, the high affinity of the molecules to waxy surfaces “sticks” the fungicide to these unsprayed tissues.

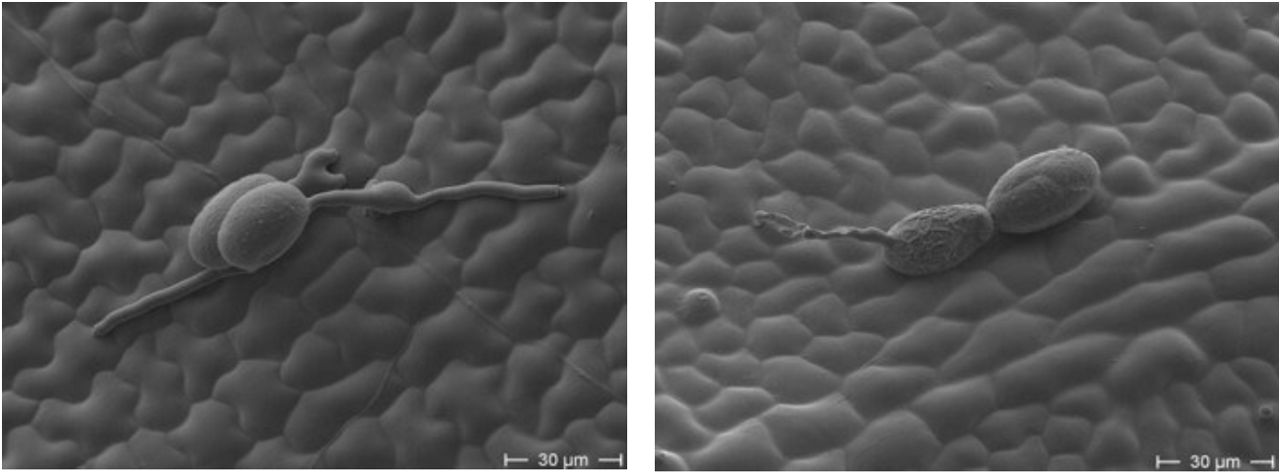

QoIs limit fungi energy production to prevent spores from germinating on the leaf surface (Figure 5).

Figure 5. Fungal spore growth on leaf surface (left) and Trifloxystrobin treated fungal spores (right).

QoIs can trigger physiological reactions in the plant to help contribute to plant health. Physiological reactions include the inhibition of ethylene production in the plant, improved utilization of limited resources, and lignification of cell walls. Inhibition of ethylene slows stress reactions, contributing to chlorophyll production and greener plants, referred to as the “greening effect” (Figure 6). As plants mature, reduced ethylene production also slows the senescence process, allowing plants to stay greener, longer.

Figure 6. The greening effect of QoI fungicides on moisture stressed soybean. Photo taken at R6 growth stage.

Slowed stress reactions also means that plants may be slower to wilt and quicker to recover where moisture is limited and later supplied (Figure 7).

Figure 7. Plant 1 is untreated. Plant 2 is treated with a product containing trifloxystrobin. Both plants are under the same moisture stress. Plants treated with QoI fungicides can have slowed stress reactions which may result in a delay in wilting where moisture is limited.

*Fungicides do not replace sufficient moisture and where moisture is severely limited a negative effect could occur due to the delayed stress reaction caused by the QoI fungicide.

Physiological reactions in the plant can also strengthen cell walls leading to increased standability. The improved utilization of limited resources (such as nitrogen) can also contribute to the greening effect.

There are nine chemical groups of QoIs. Some common QoIs are trifloxystrobin, azoxystrobin, fluoxastrobin, picoxystrobin, and pyraclostrobin.

As QoIs are effective at preventing spore germination, they should be used early in the disease cycle. QoIs have a high-risk rating for resistance. Wherever possible they should be applied in mixtures with fungicides from other groups. Each mix partner should be used at a rate which provides effective disease control of the targeted disease. Avoid using split applications or reduced and repeated rates of QoI fungicides. Limit the number of applications of QoI fungicides with rotation to different modes of action if additional fungicide applications are necessary.1

See FRAC recommendations for additional information on fungicide resistance management for specific crops.

Group 29- Uncouplers of oxidative Phosphorylation

Group 29 fungicides, such as fluazinam, inhibit fungal respiration. Group 29 fungicides have a low risk for resistance and are not cross-resistant with other Respiration Inhibitors. As such, they can be a good option for resistance management in registered crops and pathogens.1

Sterol Biosynthesis Inhibitors (G)

Group 3- Demethylation inhibitors (DMIs)

DMIs are broad-spectrum fungicides. They are locally systemic to systemic and can be preventative and curative. They work by disrupting the membrane of the fungi cells and organelles after spores have germinated (Figure 8).

Figure 8. Septoria tritici blotch. Left: Untreated. Right: Treated with prothioconazole.

Triazoles are the largest chemical group of DMIs and may be mistakenly used to describe the DMI group entirely. Some commonly used triazoles are tebuconazole, propiconazole, metconazole, tetraconazole, flutriafol, cyproconazole, and difenconazole. Triazolinthiones are another chemical group in the DMI group. Prothioconazole is a triazolinthione. Prothioconazole has a very broad control spectrum and excellent residual activity. It is slower acting because it penetrates more slowly than several triazole molecules such as tebuconazole or flutriafol. Prothioconazole is highly mobile and is translocated upwards through the xylem.

DMIs have a moderate-risk rating for resistance. Best management practices can help to maintain the effectiveness of these fungicides. Be aware of high disease pressure with high-risk pathogens (such as Alternaria, grey mould, or powdery mildew) and consider limiting repeated applications of DMI-only fungicides in these cases. Consider rotating fungicide groups or applying DMI fungicides in mixture with another effective non-DMI mode of action. Use label rates at the recommended timing for effective control of the disease.1

Multi-site Activity (M)

Groups M1 to M12 - Fungicides with an “M” mode of action have multi-site activity and are low-risk to resistance. They are contact fungicides which provide protection with no curative abilities. Commonly used fungicides in these groups are copper, mancozeb, and chlorothalonil. Copper is in Group M1, inorganic copper. Mancozeb is in Group M3, dithiocarbamates and relatives. Chlorothalonil is in Group M5, chloronitriles.

Biologicals with Multiple Modes of Action (BM)

Group BM2 - Microbial fungicides such as Bacillus subtilis are classified as BM2, microbial. These can be used as an alternative option in organic cropping or for resistance management.

Resistance Management

Reduce selection pressure on a single mode of action by rotating between fungicide groups, applying multiple effective modes of action in a mixture, and by following the label for rate, timing, and interval of application. QoI (Group 11) and SDHI (Group 7) fungicides are at a higher risk for fungicide resistance than DMIs (Group 3). Consider the pest as well. Some pathogens are more prone to developing resistance than others. Specific recommendations for resistance management by crop, pest, and fungicide can be found at https://www.frac.info.

Sources:

1 Fungicide Resistance Action Committee. https://www.frac.info.

Legal Statements

Performance may vary from location to location and from year to year, as local growing, soil and weather conditions may vary. Growers should evaluate data from multiple locations and years whenever possible and should consider the impacts of these conditions on the grower’s fields.

Tank mixtures: The applicable labeling for each product must be in the possession of the user at the time of application. Follow applicable use instructions, including application rates, precautions and restrictions of each product used in the tank mixture. Bayer has not tested all tank mix product formulations for compatibility or performance other than specifically listed by brand name. Always predetermine the compatibility of tank mixtures by mixing small proportional quantities in advance. ©2021 Bayer Group. All rights reserved. 1026_S2_CA